We’re very happy to share Techlore’s video review of the BusKill Kill Cord.

Can’t see video above? Watch it on PeerTube at makertube.net or on YouTube at youtu.be/Zns0xObbOPM

We’re very happy to share Techlore’s video review of the BusKill Kill Cord.

Can’t see video above? Watch it on PeerTube at makertube.net or on YouTube at youtu.be/Zns0xObbOPM

We’re happy to announce that BusKill is presenting at DEF CON 32.

What: Open Hardware Design for BusKill Cord

When: 2024-08-10 12:00 – 13:45

Where: W303 – Third Floor – LVCC West Hall

Update 2024-09-04 Added slide deck pdf

Today we’re ecstatic to publish our first demo showing a homemade BusKill Cable (in the prototype 3D-printed case) triggering a lockscreen.

While we do what we can to allow at-risk folks to purchase BusKill cables anonymously, there is always the risk of interdiction.

We don’t consider hologram stickers or tamper-evident tape/crisps/glitter to be sufficient solutions to supply-chain security. Rather, the solution to these attacks is to build open-source, easily inspectable hardware whose integrity can be validated without damaging the device and without sophisticated technology.

Actually, the best way to confirm the integrity of your hardware is to build it yourself. Fortunately, BusKill doesn’t have any circuit boards, microcontrollers, or silicon; it’s trivial to print your own BusKill cable — which is essentially a USB extension cable with a magnetic breakaway in the middle

Mitigating interdiction via 3D printing is one of many reasons that Melanie Allen has been diligently working on prototyping a 3D-printable BusKill cable this year. In this article, we hope to showcase her progress and provide you with some OpenSCAD and .stl files you can use to build your own version of the prototype, if you want to help us test and improve the design.

ⓘ Note: This post is adapted from its original article on Melanie Allen’s blog.

In our last update, I showed a video demo where I succesfully triggered a lockscreen using a BusKill prototype without the 3D-printed body for the case and N35 disc magnets. I realized that the N35 disc magnets were not strong enough. In this update, I show a demo with the prototype built inside a 3D-printed case and with (stronger) N42 and N52 cube magnets.

Can’t see video above? Watch it on PeerTube or on YouTube at youtu.be/vFTQatw94VU

We’re happy to announce that we were successfully able to initiate a BusKill lockscreen trigger using a 3D-printed BusKill prototype!

While we do what we can to allow at-risk folks to purchase BusKill cables anonymously, there is always the risk of interdiction.

We don’t consider hologram stickers or tamper-evident tape/crisps/glitter to be sufficient solutions to supply-chain security. Rather, the solution to these attacks is to build open-source, disassembleable, and easily inspectable hardware whose integrity can be validated without damaging the device and without sophisticated technology.

Actually, the best way to confirm the integrity of your hardware is to build it yourself. Fortunately, printing your own circuit boards, microcontroller, or silicon has a steeper learning curve than a BusKill cable — which is essentially just a USB extension cable with a magnetic breakaway in the middle.

Mitigating interdiction via 3D printing is one of many reasons that Melanie Allen has been diligently working on prototyping a 3D-printable BusKill cable this year. In this article, we hope to showcase her progress and provide you some OpenSCAD and .stl files so you can experiment with building your own and help test and improve our designs.

ⓘ Note: This post is adapted from its original article on Melanie Allen’s blog.

Last month, I successfully triggered a lockscreen event using our 3D-printed BusKill prototype.

We’re happy to announce that we’ve had good progress on the design of the 3D printable BusKill USB-A magnetic breakaway couplers this year!

While we do what we can to allow at-risk folks to purchase BusKill cables anonymously, there is always the risk of interdiction.

We don’t consider hologram stickers or tamper-evident tape/crisps/glitter to be sufficient solutions to supply-chain security. Rather, the solution to these attacks is to build open-source, disassembleable, and easily inspectable hardware whose integrity can be validated without damaging the device and without sophisticated technology.

Actually, the best way to confirm the integrity of your hardware is to build it yourself. Fortunately, printing your own circuit boards, microcontroller, or silicon has a steeper learning curve than a BusKill cable — which is essentially just a USB extension cable with a magnetic breakaway in the middle.

Mitigating interdiction via 3D printing is one of many reasons that Melanie Allen has been diligently working on prototyping a 3D-printable BusKill cable this year. In this article, we hope to showcase her progress and provide you some OpenSCAD and .stl files so you can experiment with building your own and help test and improve our designs.

ⓘ Note: This post is adapted from its original article on Melanie Allen’s blog.

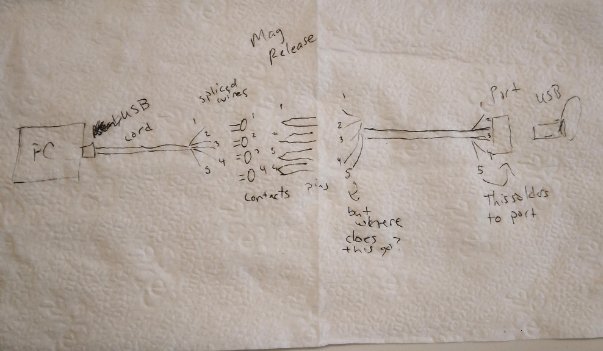

A few years ago, Michael asked me if I was interested in developing a 3D-printed case for the magnetic breakaway. He enumerated the following design requirements:

However, over the past years’ iterations, we adjusted the requirements: